How do you pick the right metal joining method/s for your enclosure? Our August Metal Design Tips covered metal thicknesses and why it’s critical to select the right metal thickness for your enclosure.

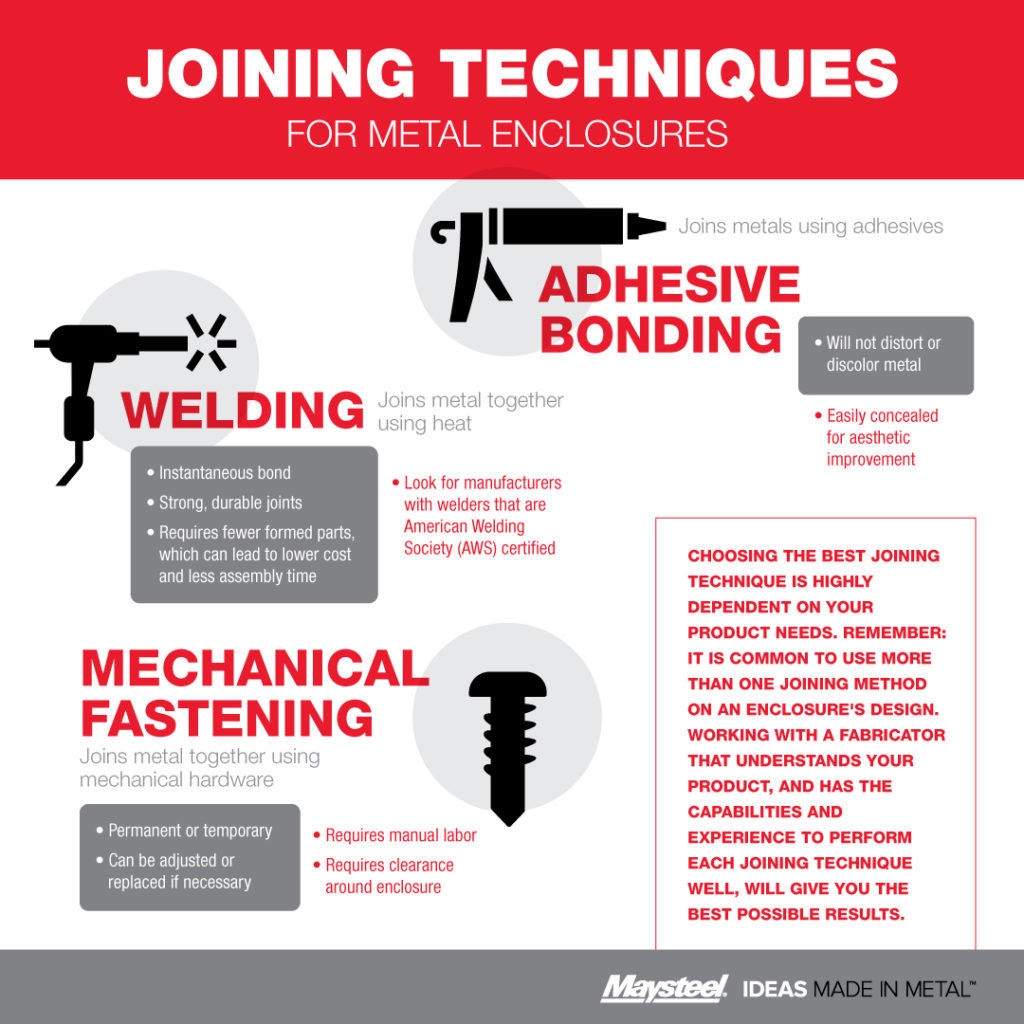

Here, we will help answer which joining method is right for your enclosure by reviewing three techniques:

We will also review the pros and cons of each. Let’s dive in!

Welding is a common process in sheet metal fabrication for creating permanent bonds, especially for metal enclosures. Two common types of metal welding are Metal Inert Gas (MIG) welding and Tungsten Inert Gas (TIG) welding.

MIG welding is a flexible process utilized for various metals, industries and applications. It’s also more cost-effective than TIG welding.

TIG welding is ideal for highly cosmetic applications using metals such as aluminum and stainless steel. TIG welding uses a lower temperature than MIG welding, making it less likely to distort or discolor metals. You can find examples of TIG welding on electronic enclosures, NEMA 4 enclosures and NEMA 4X enclosures.

While these are only two types of welding processes, there are many reasons why companies choose to weld their metal enclosures. Welding creates a strong joint between parts/components; joints are points where the metal is connected. Although different weld techniques result in different joint types, a strong joint equals a robust and durable product. They are also choice if you are looking for a leak-proof enclosure.

When comparing welding to mechanical joining methods, one benefit is that welding creates an instantaneous bond. There is no need to drill holes in the parts before bonding or to install fasteners manually. These processes can prove time-consuming and leave room for human error.

Welding can also lead to less formed parts for your enclosure. Why is this important? Simpler, welded components can lead to lower cost and less assembly time than manually joining pieces together.

Like everything, there are drawbacks to welding. For the best results, welding processes should be completed by a trained/certified welder. For example, when looking for a fabrication supplier, see if they have in-house training for their welders, verify their experience levels and ask if they hold AWS (American Welding Society) certifications.

Welding can also prove difficult with highly cosmetic products. Again, it’s vital to use a skilled weld team. Additional defects/discoloration require metal finishing, which adds both time and cost to your project.

If you are welding your enclosure in-house, keep in mind welding can take up a great deal of real estate. Take a Bluco weld table, for example. It’s critical, especially for large enclosures, to have the available real estate to perform the functions. In addition to the physical space necessary for welding, weld fixtures can be costly. Now let’s look at mechanical joining/fastening.

Mechanical joining/fastening is very different from welding processes or adhesive bonding. This joining process involves mechanical hardware and fasteners such as rivets, nuts, bolts and screws to join multiple parts together. This can also be known as threaded fastening. Mechanical joining and fastening forms a stronger joint than adhesives but is not as strong as welded joints.

Mechanical joining can be permanent or temporary. Riveting is a permanent joining method, while fasteners such as screw, bolts and nuts are temporary joining methods. Why? Fasteners can be taken off with simple tools, while rivets must be ground or drilled out of the parts.

Unlike welding, hardware or fasteners used in mechanical joining can be adjusted or replaced if necessary. Also, unlike welding, there is no heat used in the process, eliminating the metal’s risk of discoloration and distortion. Hardware comes in many types, shapes and sizes, allowing you to choose the option that best fits your enclosures.

So, what’s the catch? When you load up an enclosure design with hardware, the main downfall is the manual labor that accompanies it. Manual labor takes both time and precision. You can expedite this process with an automated press, but that is a significant company investment. Some fasteners also require more manual labor than others. Take rivets, for example, which must be shot manually.

Additional concerns with hardware include the need to count and keep track of each piece. It is also easy to miss hardware during the assembly process creating quality issues, especially if your enclosures require a high level of seal integrity such as NEMA 4 or NEMA 4x enclosures.

A final concern with mechanical joining is ensuring you have enough clearance within your enclosure to install or remove hardware. Whether it be during the assembly process or for routine maintenance, you need to have enough room to get a screwdriver, drill or another tool into the space.

Adhesive bonding is used for structural bonding in specific industries, such as the automotive industry for vehicle panels. Our engineering team typically utilizes welding and mechanical joining methods for structural components when it comes to complex sheet metal enclosures. We will use adhesives aesthetically for additive detail where welding and fasteners should not be visible. Adhesive bonding is excellent for this because, like mechanical joining and fastening, adhesive bonding will not distort or discolor metal, unlike welding processes. Also, it easy to hide adhesive bonding because, “...adhesives are generally hidden between two substrates, which can offer aesthetic improvements over welding and mechanical fasteners,” shared Assembly magazine.

Adhesive bonding sounds like a great aesthetic solution, but what are the disadvantages? A considerable drawback is the strength of the joint. Out of the three joining techniques mentioned here, adhesive bonding is the least durable. It is also crucial to thoroughly test adhesives on your specific enclosure to protect them from failure in the field. Also, the Fabricator wrote, “some adhesives require equipment with a unique construction for proper application. For example, acrylic adhesives must be applied with stainless steel equipment.” Adhesives also require curing time, while joining methods like welding are instantaneous.

How you join your enclosures together affects critical enclosure characteristics, including durability and strength. Here we reviewed:

Deciding upon the best joining technique is highly dependent on your product needs, and you can use the pros and cons above to help you make your selection. Keep in mind it is not uncommon to use more than one joining method on an enclosure’s design. Many of our complex enclosures require all three.

Are you looking for more metal enclosure design tips? Read our August post covering metal thicknesses for your enclosure.

Do you have a current project need? Get in touch with our team!

©2020 Maysteel Industries, LLC

Stay up to date with all Maysteel manufacturing news, updates, and trends. If you don't love it, unsubscribe with just a click.